Grade Scanning

Porter’s RT Grade Scanning Software Add‐on provides the ability to detect surface defects on logs and cants and factor them into the optimum rotation and sawing solution further increasing grade, value and lumber outturn from every log. Typically, logs are scanned in front of an automated log turner or directly on a primary break down infeed.

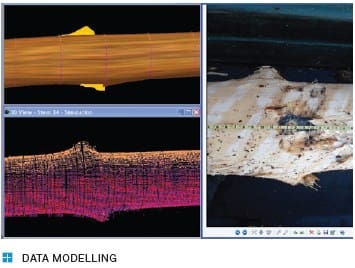

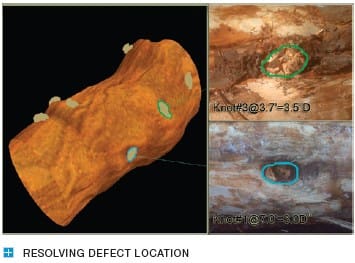

Full 360 degree Ultra High Definition (UHD) Profile Scanning is utilized to build a complex three dimensional log model that now includes mapped surface irregularities with other standard geometrical data. This model is then used to calculate surface defects such as knots, catfaces and gouges resulting in a “Log Grade” being established for every log. The Optimization System can now use this grade information to provide a better Optimum Rotation and Canter Solution factoring products of different grades and values.

- Detects knot, catfaces and gouges based on “user configurable” parameters that control the recognition methodology.

- The user has the ability to fine tune parameters specific to each defect type based on height, depth, width and length of the surface anomaly

- Records all defects with their locations and dimensions for every log

- Grades each log into three categories based on highly customized defect points system

- Grade information is factored into the Optimum Rotation Solution for the Log Turner as well as the Primary Breakdown System

- Custom mill management reporting

Porter offers many levels of product support to ensure your continued satisfaction with our systems

- Free telephone technical support for the life of the system including troubleshooting your system over Internet/VPN

- After Hours Emergency support

- Spare optimization parts stocked at our Richmond facility